Our Services

Complete Plant Engineering Solutions

From design to deployment, we provide end-to-end premium bulk solids handling solutions

What We Offer

Complete Plant Engineering Solutions

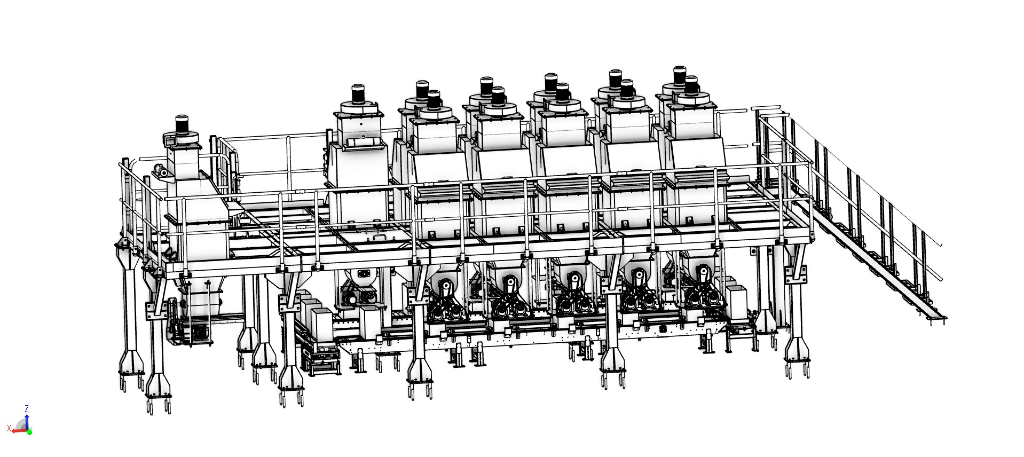

Turnkey Bulk Solids Handling

Complete end-to-end solutions for premium bulk solids handling plants, from conceptualization to commissioning.

Tire & Rubber Mixer Feeding Pneumatic Conveying System

Specialized pneumatic conveying systems for carbon black, silica, and other raw materials.

ASCW

Automated Small Chemicals Weighing and Batching System for precise and repeatable handling of chemicals.

Zen-3k (Rubber Compounding Automation Control System)

Advanced Process Control Systems for rubber mixing room facilities. Features comprehensive recipe management.

Complete Solutions

Turnkey Bulk Solids Handling

Complete system integration through a single window

Comprehensive Turnkey Bulk Solid Handling Solutions

ZENESIS Plant Engineering provides complete turnkey bulk solid handling solutions for the entire system integration through a single window - from Conceptualisation to Commissioning, covering Raw Material Inward to Finished Good Packing.

Our Approach

- ➤ Single Window Integration - One point of contact for entire project

- ➤ End-to-End Solutions - From concept to commissioning

- ➤ Complete Coverage - Raw material inward to finished goods

- ➤ Customised Technologies - Tailored to your specific needs

The Turnkey Solutions Include:

- ○ Bulk Solids (Powder, Granular) Intake & Storage

- ○ Mixer Feeding System

- ○ Liquid Handling

- ○ Polymer Handling

- ○ Small Chemicals Weighing And

Batching

- ○ Mixer Aspiration

- ○ IT, Software & Automation

Specialized Systems

Tire & Rubber Mixer Feeding Pneumatic Conveying System

Carbon Black Granulated and Silica

Our pneumatic conveying systems are specifically designed for feeding raw materials to Banbury Mixer / Intermix / Kneader. This system is mainly applicable for conveying powdery and granular materials such as carbon black, silica, zinc oxide, clay, calcium carbonate, rubber powder, and more.

- ➤ Environmental protection & high automation

- ➤ Convenient installation & flexible layout

- ➤ Large conveying capacity & long distance

- ➤ Low conveying velocity (low fines generation)

- ➤ No pipe blocking & safe operation

- ➤ Highest reliability

Air source treatment unit, big bag unloading device, high pressure rotary feeder, dense phase pressure vessel / blow tank, two-way diverter, conveying pipeline, and PLC based control system.

Specialized Systems

Automated Small Chemicals Weighing and Batching System (ASCW)

Our automated small chemicals weighing and batching system ensures accurate, repeatable, and efficient handling of powder, flaky, and granular materials. The system automatically weighs, dispenses, and verifies chemicals based on predefined recipes, reducing manual effort and ensuring consistent production quality.

Where It Is Used

- • Tyre and rubber manufacturing

- • Plastics and polymers

- • Chemical processing

- • Friction materials

- • Powder metallurgy

- • Lithium batteries

- • Ink and dye industries

Key Benefits

- ➤ High weighing accuracy

- ➤ Batch consistency

- ➤ Reduced manual handling

- ➤ Clean, dust-controlled operation

- ➤ Flexible bagging options

How It Works

- • Materials dispensed per recipe

- • Auto basket tare weight

- • Batch verification scale

- • Automated batch collection

- • Continuous operation cycles

IT & Automation

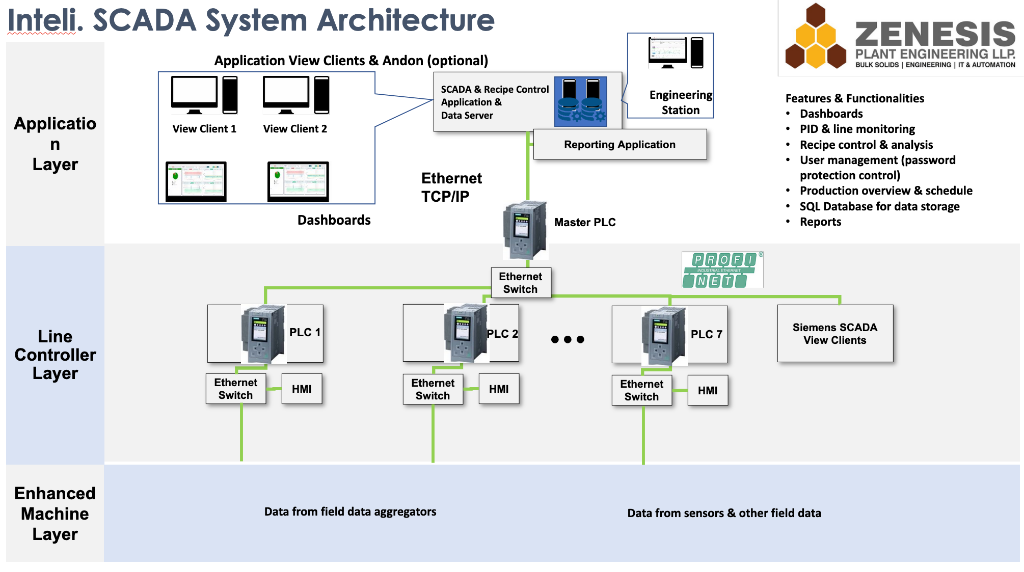

Zen-3k Process Control Systems

IT For the Mixer Feeding Systems (Rubber Compounding)

Process Control Systems in the Rubber Mixing Room Facilities

- ➤ Process Control Systems

- ➤ Automation

- ➤ Mixer Control

- ➤ Recipe Management

- ➤ Batch tracking

- ➤ Master Data Management

- ➤ Production Data Acquisition

- ➤ Analysis

Features & Functionalities

- • Dashboards

- • PID & line monitoring

- • Recipe control & analysis

- • User management

- • Production overview

- • SQL Database storage

- • Comprehensive Reports

Why Choose Our Solutions

Service Excellence

Custom Design

Every solution is tailored to your specific requirements, process, and space constraints.

⚙️ Proven Technology

Leveraging 30+ years of field-proven technologies and best practices from 11+ projects.

🔧 Full Integration

Seamless integration with existing equipment and infrastructure for minimal disruption.

🇮🇳 Make In India

Make in India approach with local engineering, manufacturing, and support services.

Data Driven

Advanced analytics and monitoring for continuous improvement and optimization.

Energy Efficient

Optimized designs for minimal energy consumption and reduced operating costs.

🛡️ Safety First

Compliance with international safety standards and best practices in all designs.

🔄 After-Sales

Comprehensive support, maintenance, and spare parts services for long-term reliability.

Need a Custom Solution?

Our engineering team is ready to design the perfect bulk solids handling solution for your specific requirements.